Alton Paper Mill & Alton Battery Company

Alton Paper Mill - Closed 1909

Alton had a long connection with the paper making industry, a leaflet produced by the Curtis Museum in 2019 contained this synopsis:

‘The first known paper maker in Alton was Benjamin Godwin who was followed in 1768 by William Barrett - who went bankrupt. Robert Myears took over and, when he died in 1780, the mill was a ‘two-vat paper-mill and a corn mill under one roof’. William King was the next person to make paper in Alton and it was he who appears to have formed Kings Pond to give a head of water. 1796 saw the arrival of John Edward Spicer from Buckinghamshire and his family ran the paper mill, except for a short time in the late 1840s and early 1850s, until 1909.’

Rumours of redundancy or relocation to a new mill at Eysnford in Kent, appear to have begun sometime in 1908, eventually being confirmed on or around 23rd September, when it was announced that the first batch of employees would be transferred in 6 weeks’ time. From that point output was scaled down until closure.

The mill site stood empty for a number of years, there were reports it had been sold in 1911, however no evidence could be found to substantiate the claim. In early January 1913, the papermaking plant and machinery were listed for sale by way of auction. The building itself remained unsold. It was called into use during the First World War, when German prisoners working the local farms were billeted there.

The site had a new lease of life in 1919, when the Alton Battery Company acquired it.

Alton Battery Company 1919-1958

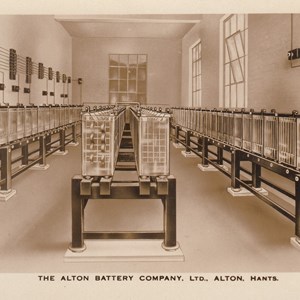

Founded by Clifford Clare Rattey, the Alton Battery Company acquired the long disused paper mill formerly owned by the Spicers in the latter half of 1919. The business grew, reaching the international market, leading to installations worldwide! A newspaper article from October 1929 reported:

‘Mr. C. C. Rattey, Chairman of Alton Battery Co., has gone on a world trip on behalf of his firm. After travelling to the United States, Canada, and the Far East, he will return via the Straits Settlements, Ceylon, and India.’

A recently discovered brochure from 1933, indicates that international marketing trips were fruitful, with Alton Batteries reported in use worldwide:

Argentina, Australia, Burma, Brazil, Canada, China, Columbia, Egypt, Fiji, Greece, India, Italy, Lithuania, New Zealand, Portugal, Peru, South Africa and the United States, to name a few!

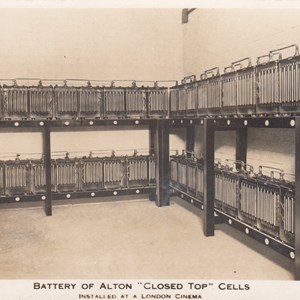

Alton Batteries were also in use across the United Kingdom, from Government & Local Authority Buildings, H.M. Armed Forces, Hospitals, Railway Companies, Telephone Exchanges*, The B.B.C., Country Houses and Cinemas (An example of which you can see above)

*Including the Alton Telephone Exchange on Anstey Road, built in 1936.

In 1957 news began circulating that the company would close, eventually closing in 1958. An extract from an article in the Alton Papers number 12 tells us that:

‘The coming of the National Grid ended the business and the company was sold to Chloride Electrical Company and the men could either work for them or be made redundant’

Prior to the company closing it was announced that jobs would be found within the industry for as many Alton employees as possible, but those who would be made redundant would receive at least 4 weeks’ notice. They would also receive compensation based on age and length of service.